Standard Vs Custom Mezzanine Floors: Pros & Cons

If your business is running out of room to operate efficiently, a mezzanine floor can transform your warehouse into a more functional and valuable space. However, choosing between a standard modular system and a structure that's custom-designed specifically for the space can be a difficult decision when you're looking to future-proof your business.

Here we investigate the pros and cons of each option, from initial cost and installation considerations to long-term ROI, to help guide you on the smartest investment for your business.

What Are Standard Mezzanine Floors?

Standard mezzanine floors are freestanding platforms that make use of vertical space in a building, typically covering part of the floor area to increase storage capacity or workspace quickly and cost-effectively.

Unlike custom-built systems, standard mezzanine floors are pre-engineered, modular structures with set load-bearing capacities, widths and heights. This makes them more affordable and easier to install than bespoke solutions.

This type of mezzanine structure is best for companies that are looking for a non-permanent way to increase storage space in warehouses or retail stores with minimal disruption while still complying with Australian building codes.

What Are Custom Mezzanine Floors?

Custom mezzanine floors are tailored to the operational needs of businesses, offering more flexibility in design, load requirements and access solutions.

Because they are uniquely designed for each building, they can be made to fit around walls or machinery and can be multi-level or single-level structures. A custom load capacity also means they can safely support a business's unique operational needs, whether used to gain office space or store heavy equipment. They can also be fitted with custom access solutions like staircases, handrails and pallet gates to maximise productivity.

Custom mezzanine floors are best suited to companies looking to accommodate business growth and future needs with a more permanent solution that integrates with existing infrastructure. They are also more suited to buildings with irregular layouts or height restrictions.

Pros and Cons of Standard Mezzanine Floors

Standard mezzanine floors or mezzanine floor kits have a shorter lead time, and they can be installed in warehouses, factories and industrial settings faster, therefore causing less disruption than a custom-designed solution. They are more cost-effective, and because they are modular, they can be added to or removed as required.

However, standard designs may not be suitable for all building layouts and depending on their intended use, may not suit the building's aesthetic as well as a custom solution.

Pros and Cons of Custom Mezzanine Floors

Custom mezzanines are designed specifically for their intended purpose, so they are particularly suitable for ensuring compliance and structural integrity when used for heavy-duty loads. Their flexible design can also help businesses maximise their usable space and increase operational efficiency with tailored solutions.

However, key considerations when installing a custom mezzanine should include longer lead and installation times, a higher initial cost and more complex planning requirements.

Factors to Consider When Choosing

There are several factors to weigh when choosing between a standard and a custom mezzanine. The first is budget and your business's future needs. Standard mezzanines are less expensive and, as they are modular, they are more easily reconfigured or added to if required.

The amount of available floor space and the configuration of the building will also play a role in which solution is more suitable, as will your ability to comply with Australian safety standards, including fire safety and other worker safety regulations.

Cost Comparison

When it comes to the initial expense of installing a mezzanine, standard or mezzanine floor kits are more cost-effective.

Installation of a standard mezzanine is also less expensive and causes less disruption to business operations. Some mezzanine kits, including those from AWS, can be self-installed, while custom mezzanines require higher labour costs as they normally include multiple trades and site coordination.

In terms of a business's return on investment, this depends on the complexity of the structure and its use. However, generally speaking, a custom-designed mezzanine's potential to increase property value and create a more efficient building layout means it represents the best value for money.

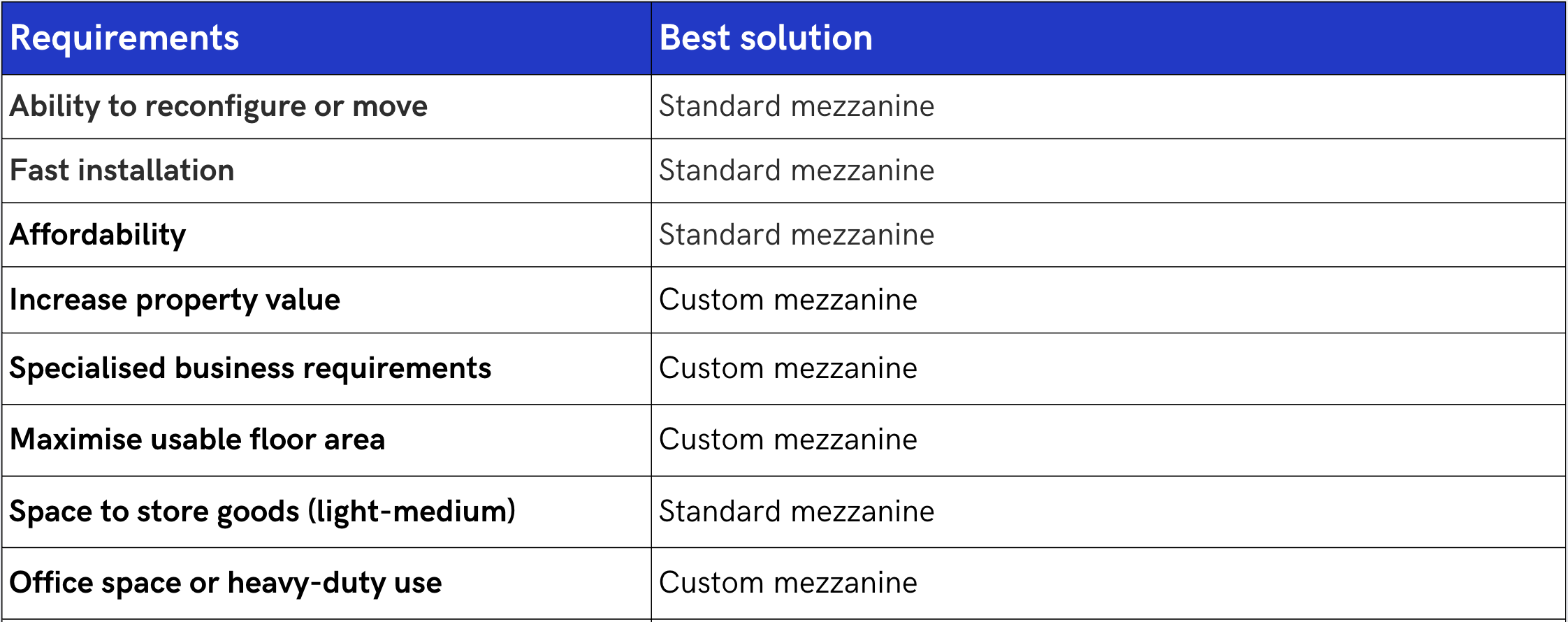

When to Choose Standard vs Custom

Ready to Get Started on Your Mezzanine Solution?

Mezzanine floors are the most efficient way to expand your business without the expense and inconvenience of building or moving premises. Whether you choose a custom structure or a standard solution will depend largely on its intended use, your floor space requirements, budget and your investment and business goals.

At AWS, all of our mezzanines, including our mezzanine floor kits, are custom-designed for your warehouse and your requirements. This means that you can have your mezzanine quickly but built so that it looks like it belongs in the space. If it's a custom structure you're looking for, we also specialise in large-scale solutions to suit any site. Contact us today to discuss the best type of mezzanine floor to help your business move in the right direction.

Frequently Asked Questions

What are the Australian standards for mezzanine floors?

Mezzanines must meet a range of standards to ensure they are safe and compliant. These include structural integrity, fire safety and access.

What is the best flooring for a mezzanine?

The best flooring for a mezzanine depends on how you intend to use the space. That is, how heavy loads will be, what sort of wear and tear the floor is exposed to, and your budget.

What are the disadvantages of a mezzanine floor?

Mezzanine floors are not the best space-saving solution in all cases, including where they might interrupt the flow of traffic, limit the use of ground floor space, or require extensive reinforcements to a building's existing foundations.

Which material is best for a mezzanine floor?

AWS prefers to fabricate our mezzanine floors out of Australian-made steel because it offers durability and strength. It's also low maintenance and easily customised.